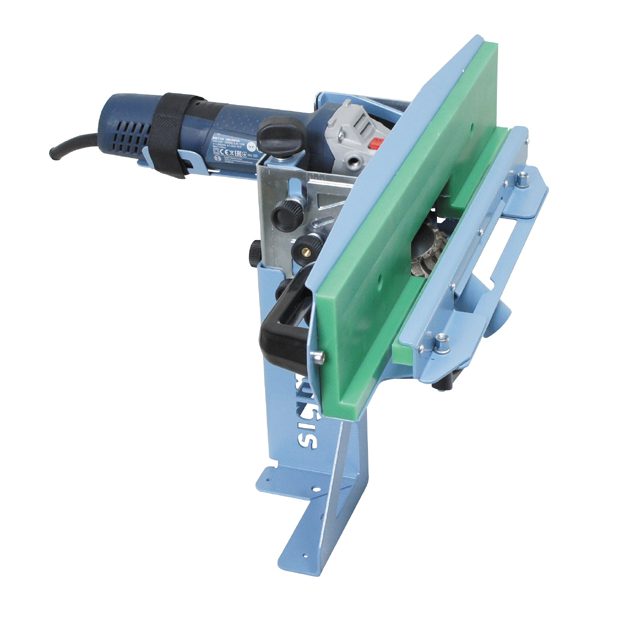

JOLLY-EDGE

CARATTERISTICHE TECNICHE

La “JOLLY-EDGE” può eseguire due lavorazioni differenti:

– “JOLLY” del bordo della piastrella, tramite disco da taglio.

– “MEZZO TORO” (profilatura) del bordo della piastrella, tramite mola sagomata.

Scivolando in appoggio sul bordo della piastrella / lastra (gres, marmo, granito, ecc..) garantisce l’uniformità della lavorazione su tutta la lunghezza dello spigolo, copiando esattamente le curve fisiologiche della lastra.

Esecuzione di Jolly a qualsiasi angolazione compresa fra 40° e 50°, nella configurazione “Mezzo Toro” permette l’esecuzione di smussi rotondi (BULL) con raggio 6-8-10 mm, può lavorare in un’unica passata piastrelle con spessore 5-20mm e dimensione da 30 cm a infinito.

Predisposta per l’aspirazione delle polveri, per il taglio a secco senza diffondere polvere nell’ aria.

Attacco universale M14 per smerigliatrice da 700 – 1400 W.

Completa di disco da taglio d.115 turbo.

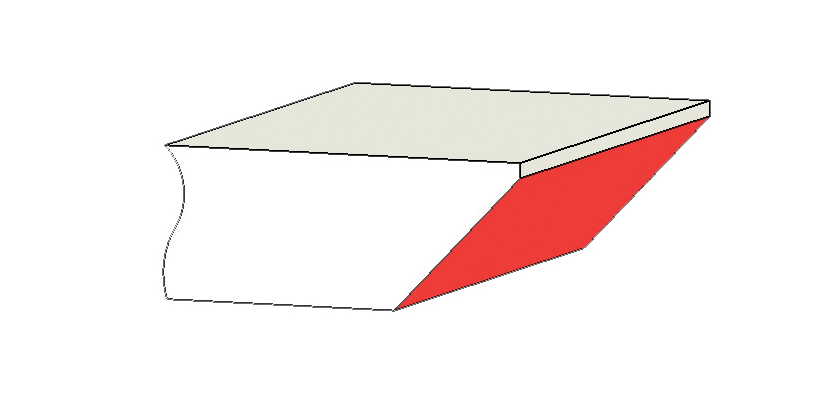

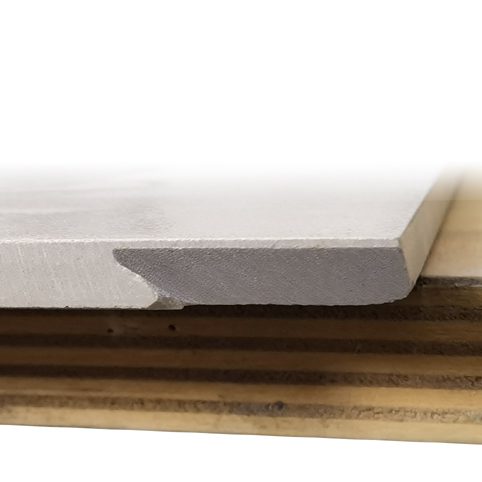

vERSIONE “JOLLY”

Nella configurazione “Jolly” permette l’esecuzione del taglio a qualsiasi angolazione compresa fra 40° e 50° (Y) , con regolazione del testimone (X).

Può lavorare in un’unica passata piastrelle con spessore

5-20mm e dimensione da 30 cm a infinito .

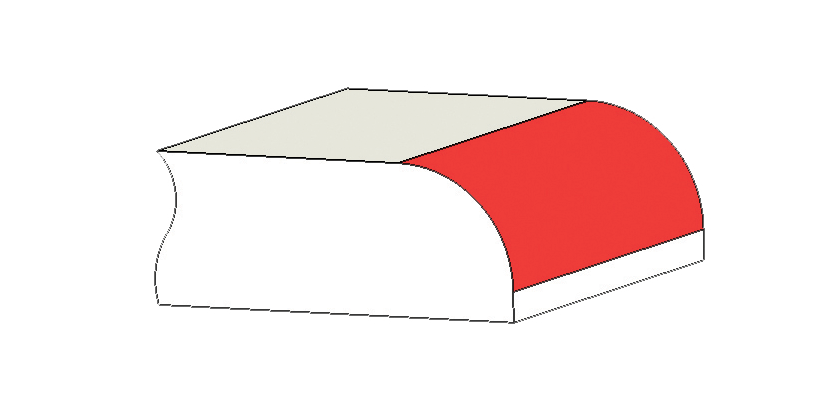

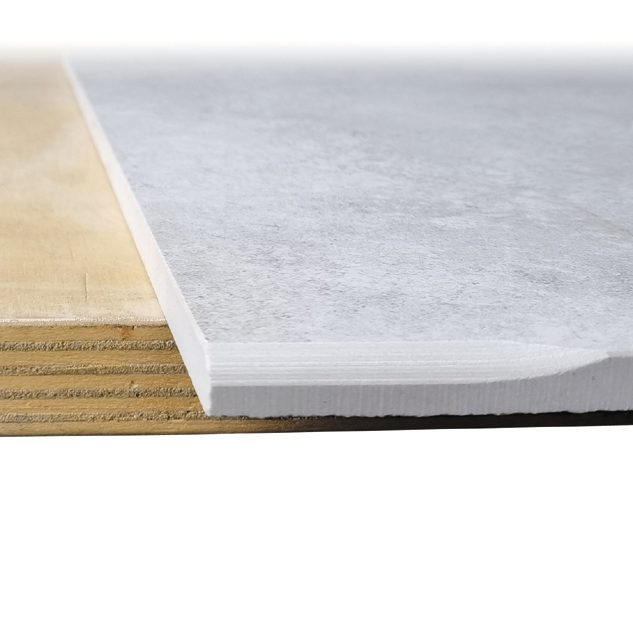

Versione “mezzo toro”

Nella configurazione “Mezzo Toro ” permette l’esecuzione di smussi rotondi (BULL) con raggio 6 – 8 – 10 mm.

E’ possibile regolare la posizione della mola ( X;Y ) per ottenere la giusta lavorazione.

LARGO PIANO D’APPOGGIO

Il largo piano d’appoggio garantisce una perfetta stabilità in fase di lavorazione, lo specifico materiale del piano ne consente una facile scorrevolezza senza graffiare la piastrella.

ATTACCO UNIVERSALE PER SMERIGLIATRICE

E’ possibile montare una qualsiasi smerigliatrice da 700 a 1400 W grazie al suo attacco universale M14.

ASPIRAZIONE DELLE POLVERI

Lavorazione senza polvere grazie all’attacco universale per l’aspirazione.

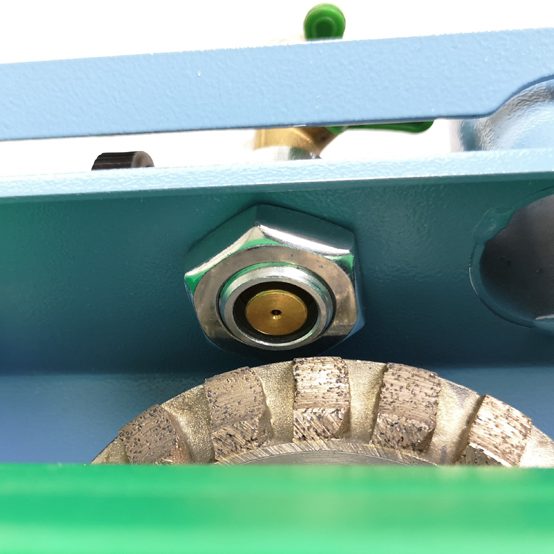

CON O SENZA ACQUA?

Studiata appositamente per poter lavorare in tutti e due i modi !

Grazie al “WATERKIT” è possibile lavorare con un getto ad acqua regolabile per la massima finitura e per limitare l’usura dell’utensile.

MANIGLIE

Durante la lavorazione sopra la piastrella, le maniglie offrono un’ottima presa evitando di perdere stabilità.

KIT FISSAGGIO Art. 37C

Particolarmente comoda per l’esecuzione in serie di piccoli pezzi come i battiscopa.

Il Kit di fissaggio permette di bloccare la macchina su un piano d’appoggio, muovendo manualmente la piastrella sulla macchina.

E’ possibile fissare il supporto sul “Banco da lavoro” Sigma senza l’uso di attrezzi.

ACCESSORI

Mola Diamantata Vacuum

Mola diamantata a VACUUM diametro 115 mm foro 22,2 mm.

Per la creazione di smussi rotondi (Toro).

Montata su Jolly-Edge per una creazione guidata dello smusso rotondo.

Alta velocità di asportazione.

Disponibile con raggio 6, 8 e 10 mm.

Possibilità di lavorazione a secco o ad acqua.

Durata indicativa 300 mt.

Mola Diamantata LUNGA DURATA

Mola diamantata a LUNGA DURATA diametro 115 mm foro 22,2 mm.

Per la creazione di smussi rotondi (Toro).

Montata su Jolly-Edge per una creazione guidata dello smusso rotondo.

Alta velocità di asportazione.

Disponibile con raggio 8 mm.

Possibilità di lavorazione a secco o ad acqua.

Durata indicativa 1000 mt.

Video

JOLLY-EDGE

Istruzioni di lavorazione.

Copyright © 2020 sigma – All Rights Reserved: sigma di Ambrogiani Sergio & C. sas – C.F/P.I. IT01085360400 – sede legale: via Gagliani,4 47814 Bellaria Igea Marina RN – iscritta al registro imprese di Rimini al N° 248826 –